ANA Mold Co., Ltd was a tool shop to become today's professional mold maker, specialized in developing, designing and making precision injection mold, and injection molding as well as CNC Machining services.We are a global service solution provider for innovation, development and production of parts that you need.

Our Milestone:

In 2000---Start a tooling shop in Shenzhen

In 2006---Certified with ISO 9001:2015

In 2013---ERP system launched

In 2016---IATF16949:2016 Certified

In 2018---Dongguan Branch Established ISO 14001 Certified

In 2023---HK Office Established

With Years of Diligent Services,Becoming Who We Are Now

Now we become an one-stop mold associated supplier company, providing mold manufacturing,injection molding as well as CNC machining services.

Our Advantage

We make sure to provide you with unparalleled quality in terms of injection mold parts at the cost that you prefer under the standard quality management system of IATF 16949:2016 and ISO 9001:2015. Typically, it is quite difficult to find the right injection molding and CNC machining services you desire. If you require reliable products, you often have to sacrifice affordability. In ANA you can have quality and cost-effective at the same time.

Once receiving the formal PO, our engineering department, tooling department and quality control department will have a meeting to make the manufacture schedule, optimize the mold design and discuss how to guarantee the critical dimensions, and how to shorten the delivery time and save the cost, meanwhile guarantee high quality of the molds in detailed ways.

Service With High Quality

Need injection molding or CNC machining service to meet your budget? No worries, we can satisefy your requirements.

Our Mission & Vision

As the leading manufacturing service provider, we offer various end-to-end holistic services that ensure maximum client satisfaction for our customers. Our mission is to provide rapid prototyping, low-volume manufacturing, and mass production without compromising on the standardization, quality, and affordability of the products. As a company, we believe in accelerating technological innovation by revolutionizing industrial manufacturing and production techniques. We empower businesses to bring new concepts to the industry by presenting them with the industry’s fastest and most inclusive production and manufacturing services.

At ANA, our vision is to manufacture good quality parts, offer excellent machining and client experience, have an unparalleled turn-around time, implement precision, quality, custom, design ability, and be a one-stop-shop solution for all of your advanced production needs. Our growth and development capabilities have always been made using a customer-centric approach so that our clients could receive the best possible digital manufacturing experience that money can buy.

Our Main Services & Capabilities

Mould Making is our main business Injection molding service at your demand need such as pilot order Custom CNC machining service is faster, easier, and more affordable than traditional machine shops using automation.

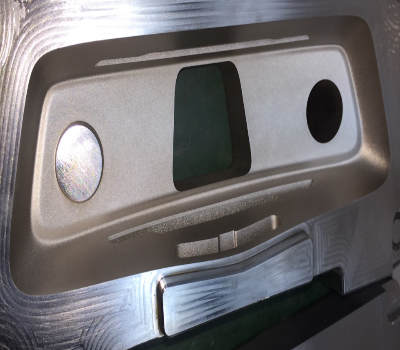

Mould Tools Making

After receiving the RFQ from customer, we will provide the tooling and molding quotation within 2 working days. When we quote the project, our engineers also will review the parts design with their expertise to communicate with you whether there are any uncertainty, or optimized option to make the mold. Any helpful suggestions to optimize the mold layout, easilier molding the part, shorten the delivery time and save the cost will be submmited together with the quotation to you for your feedback or approval.

Injection Molding

We can produce thousands of parts to pace up your product development cycle. You can choose from a large variety of materials. We keep over 100 plastic resins materials in the inventory to kick start the production. For molded end products, we have many finishing options. Our injection molding capabilities are plastic molding, insert molding, over molding, and family molding.

CNC Machining

CNC milling is to cut solid plastic and metal material into final precision parts using different axis milling processes. Milling can be also known as a perfect way of making tooling for injection mold and die casting. CNC turning is a process of machining parts with cylindrical features from metal or plastic rod stock. This process allows to make any circular parts effectively such as shafts, worms, and spheres, and it can apply to the creation of parts with complex external and internal geometries and various threads.

Equipments

High-end machines enhance our manufacturing capabilites a lot, which can secure the tolerance within customer's engineering scope and reduce defective rate and lowdown so many management cost, if you are intersted knowing what we have please let's know.